Keep Ahead of Maintenance: Investing in Top-Notch Komatsu Undercarriage Parts

Keep Ahead of Maintenance: Investing in Top-Notch Komatsu Undercarriage Parts

Blog Article

Explore Undercarriage Parts for Your Equipment Demands

Recognizing the parts that make up the undercarriage and the value of picking the right components is vital to guaranteeing smooth procedures and cost-efficient maintenance. As we check out the globe of undercarriage parts for machinery needs, a deeper understanding right into the intricacies of this essential system will certainly unravel, shedding light on the structure that supports the efficiency of your devices.

Relevance of Undercarriage Upkeep

Routine upkeep of undercarriage components is critical for making sure ideal efficiency and durability of equipment. The undercarriage of heavy equipment, such as excavators, excavators, and track loaders, plays a crucial function in sustaining the weight of the machine, providing security on different surfaces, and permitting smooth procedure - komatsu undercarriage parts. Overlooking undercarriage maintenance can cause pricey fixings, reduced efficiency, and prospective safety and security dangers

Regular evaluations of undercarriage parts, such as track chains, gears, rollers, and idlers, are crucial to recognize wear and tear early. Addressing issues quickly can protect against additional damages to the undercarriage and various other parts of the machinery. Correct cleansing of undercarriage parts is likewise needed to eliminate dirt, particles, and other impurities that can increase wear and corrosion.

Regular lubrication of undercarriage parts is one more crucial facet of maintenance to make certain smooth movement and lower rubbing between elements. In addition, tracking the usage hours and maintaining maintenance records can assist in scheduling timely substitutes and extending the total lifespan of the machinery. By focusing on undercarriage upkeep, devices owners can take full advantage of performance, lessen downtime, and eventually minimize fixing prices in the lengthy run.

Kinds Of Undercarriage Parts

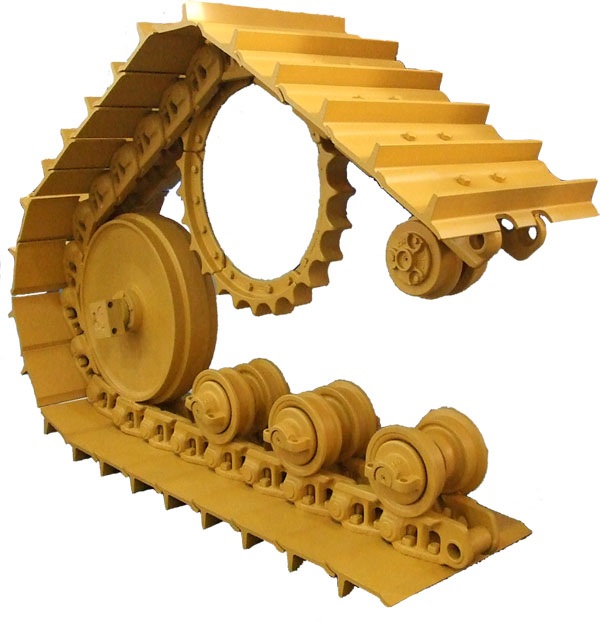

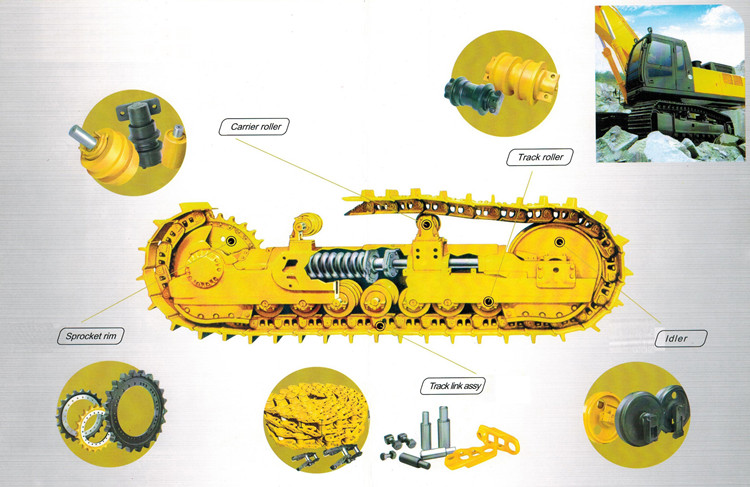

Maintenance of undercarriage parts is important for equipment long life; comprehending the various kinds of undercarriage parts is essential for effective upkeep methods. Undercarriage parts differ relying on the type of equipment and its intended usage. Usual kinds of undercarriage parts consist of track chains, track footwear, rollers, idlers, gears, and track frameworks.

Track chains are accountable for driving the equipment ahead and sustaining the weight of the equipment. Track shoes supply grip and secure the track chain from deterioration. Rollers assist in weight distribution and track assistance, while idlers assist keep correct track tension. Sprockets engage with the track chain and transfer power to move the equipment. Track structures serve as the foundation for the entire undercarriage assembly, linking all the parts with each other.

Regular evaluation and upkeep of these undercarriage components are necessary to avoid expensive repair services and downtime. By comprehending the feature of each kind of undercarriage component, equipment drivers can make sure optimum efficiency and expand the life-span of their tools.

Variables to Take Into Consideration When Picking Components

An additional essential aspect is compatibility with the specific machinery version. Each item of machinery may have one-of-a-kind requirements for undercarriage parts, consisting internet of dimension, design, and specifications. Ensuring that the parts work with the equipment will certainly help avoid functional concerns and early wear.

Additionally, it is important to take into consideration the operating conditions in which the machinery will be utilized. Aspects such as surface, climate condition, and usage frequency can all tear and impact the wear on undercarriage components. Picking components that are designed to stand up to the details operating conditions can help extend the life of the machinery and minimize maintenance expenses in the future.

Advantages of High-Quality Undercarriage Components

Top quality undercarriage components play an essential role in improving machinery efficiency and extending its functional longevity. One of the primary advantages of using top notch undercarriage parts is boosted efficiency.

In addition, top notch undercarriage components contribute to set you back savings over time. While the preliminary investment may be greater contrasted to basic components, the sturdiness and durability of premium parts decrease the requirement for frequent substitutes and repair work. This not only minimizes downtime however likewise decreases maintenance expenses, eventually leading to greater overall Recommended Reading productivity and profitability for businesses that depend on hefty equipment.

Additionally, premium undercarriage components enhance security by minimizing the danger of unforeseen failings or accidents. The boosted security and efficiency given by top notch parts develop a more secure working setting for equipment drivers and those operating in close distance to the tools. Eventually, selecting top quality undercarriage components is a critical decision that produces many advantages in terms of performance, long life, safety and security, and cost-efficiency.

Tips for Increasing Undercarriage Life-span

To make best use of the longevity of undercarriage components for equipment, carrying out proactive care methods is important for making certain optimal performance and durability. Over-tightened tracks can lead to increased tension on the undercarriage, while loosened tracks can trigger imbalance and unequal wear.

In addition, keeping the undercarriage tidy from dust, debris, and various other impurities can considerably affect its lifespan. Collected debris can accelerate wear and deterioration, influencing the overall efficiency of the machinery. On a regular basis cleaning the undercarriage with a pressure washer or a brush can assist prevent these concerns. Last but not least, operating the machinery within advised standards, such as avoiding extreme rates or overloading, can additionally add to prolonging the undercarriage life-span. By following these suggestions, machinery proprietors can make sure optimal efficiency and resilience of their undercarriage parts.

Conclusion

In verdict, keeping the undercarriage components of machinery is critical for optimum efficiency and long life. Investing in high-grade undercarriage parts not only boosts performance but additionally lowers downtime and pricey repairs.

Normal upkeep you could look here of undercarriage components is vital for making certain optimum performance and long life of machinery.Maintenance of undercarriage components is vital for equipment longevity; comprehending the different kinds of undercarriage parts is vital for effective upkeep practices.When selecting undercarriage components for equipment, it is vital to think about different elements to make sure optimum efficiency and durability.To make the most of the longevity of undercarriage parts for machinery, executing aggressive treatment practices is essential for making sure optimum efficiency and longevity. By adhering to these suggestions, machinery proprietors can make sure optimal performance and sturdiness of their undercarriage components.

Report this page